-

India's First and the Largest State Electronics Components Manufacturer

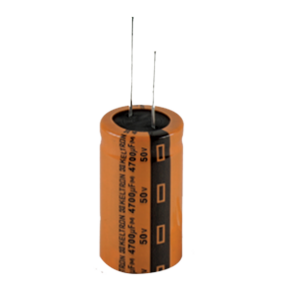

High purity Etched and Formed Aluminium foil with aluminium oxide dielectric barrier as the anode foil and an aluminium cathode foil are concentrically wound with a layer of condenser grade paper in between and after impregnation with electrolyte, the wound element is housed in an Aluminium can and then hermetically sealed using a rubber bung to form an Aluminium electrolytic capacitor. The most important advantage of the electrolytic capacitors are the higher capacitance ratio to dimensions when compared with other capacitors. This is principally due to microscopically thin dielectric layer, which produces a large capacitance per unit area. Over the years there have been continuous improvements in the etching technology of anode foil that has resulted in many-fold increase in the actual anode surface area resulting in reduction in capacitor size. The oxide dielectric layer has rectifier properties blocking current flow in one direction but offering low resistance in the opposite direction. Reversal of more than two volts will cause breakdown of the film and destruction of the capacitor. So Electrolytic Capacitor for AC applications are specially manufactured and marked Non-polar/AC. Others are polar Capacitors and therefore limited to DC applications.